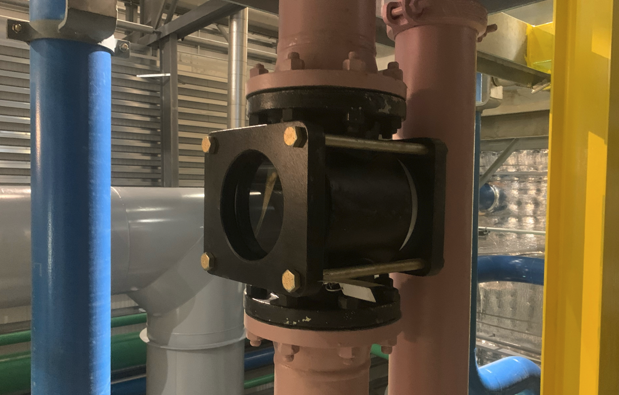

Sight Flow Indicator for Cooling Water Service - Combined Cycle Power Plant

- Mar 13, 2025

- 1 min read

Updated: Nov 4, 2025

Check out this Jacoby-Tarbox Flanged Sight Flow Indicator installed at a Combined Cycle Power Plant in the Northeast US! This unit is being used in turbine and generator lube oil cooling water service.

DID YOU KNOW? Jacoby-Tarbox’s full ASME rated line of flanged bullseye sight flow indicators have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating only ASTM listed metals in the unit’s construction.

Features:

Connections per ASME B16.5, B16.24, and B16.1

Standard fasteners per ASTM A354 and ASTM A194 complying with most piping specifications.

Tempered borosilicate glass

Units and machined and assembled in an ISO-9001 fully automated facility.

Wetted components meet NACE MR-01-75 / ISO15156-1 requirements.

Stainless steel engraved identification faceplate.

FULL BORE VISIBILITY: Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

PRESSURE DROP: Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

APPLICATIONS: Jacoby-Tarbox ASME flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.