top of page

Reliance | Jerguson | Jacoby-Tarbox | Oil Filtration Systems | Enervac | Anderson Separators | Anderson HYCOA | Anderson Filter Elements | Ernst Instruments | GPI Meters

Stories From the Field: Pulp & Paper Mill in Uruguay 📍

Every shift, operators at this paper mill in Uruguay had to climb a flight of stairs—just to check the level on a gauge. 😰 Not because they wanted the cardio… but because the camera in the control room couldn’t pick it up clearly. The Reliance team suggested upgrading to the Simpliport® 180 Bi-Color Ported Water Gage Glasses & LED Illumination Once installed, the Reliance® Simpliport made the level instantly visible on the CCTV feed. No more stair climbs. No more guesswork.

Aug 5, 20251 min read

🔧 Protect Critical Equipment with Confidence

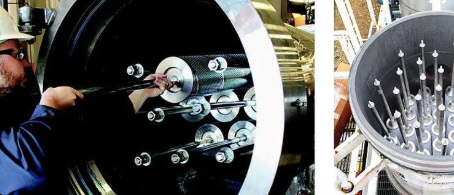

Anderson Separators & Filter Elements: In the midstream gas sector, compressors are essential for keeping product moving — but they often introduce tramp oil into the system. Left unchecked, this can lead to foaming, fouling, and costly downtime. 💵 💡 The Solution: Clark-Reliance supports the gathering, transportation, treatment, and storage stages of the midstream market with high-performance separation technology. Our Anderson Mechanical Separators (Vane & Centrifugal) and

Aug 5, 20251 min read

The Clark-Reliance Solution: LevelMax™

A major Oil & Natural Gas operator in the UAE sought to modernize their boiler level indication systems. The existing setup—a water column with flat glass gages—was no longer meeting their standards for visibility & reliability. The Clark-Reliance Solution: LevelMax™ – a comprehensive system integrating Simpliport® 180 and Smart Level Eye-Hye® technologies. We upgraded the customer to a LevelMax™ Two Instrument Assembly. The LevelMax™ system provides one of the most economica

Aug 5, 20251 min read

Protect your plants finest assets with the Jerguson® SafeView™ Shield

SafeView Shields protect operators from potential flat glass gage high - pressure leaks. Although armored glass liquid level gages are extremely reliable, leaks can occur due to deferred maintenance or the rigors of continuous operation under high pressure. Erosion of armored gage glass, for example, is often invisible without inspection of the disassembled gage. Installation of a SafeView Shield takes just a few minutes – you can easily retrofit your entire facility. They a

Aug 4, 20251 min read

bottom of page