Reliance | Jerguson | Jacoby-Tarbox | Oil Filtration Systems | Enervac | Anderson Separators | Anderson HYCOA | Anderson Filter Elements | Ernst Instruments | GPI Meters

LevelMax™ Optima

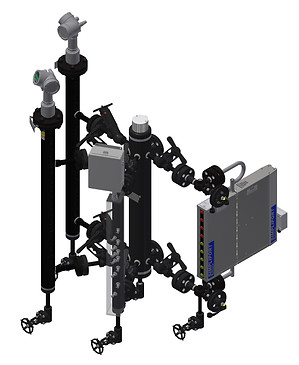

Three & Four Instrument Assemblies | Multi-Technology Boiler Level Monitoring

Three Instrument Assembly

This assembly consists of three level indicators that each operate independently. Code minimum compliance is achieved with the following instruments:

1 – SmartLevel Eye-Hye – Remote Indicator

1 – Guided Wave Radar – Remote Indicator

1 – Gage Glass – Direct Reading Indicator

This strategy could be applied to both ends of the drum to achieve redundancy.

Select the orientation of each instrument among the 3 locations on this assembly plan view to best suit your boiler installation and the structure around it, while considering operator or inspector access to the drum.

Four Instrument Assembly

This assembly consists of four level indicators that each operate independently. Redundancy and the use of multiple technologies is achieved with the following instruments:

1 – SmartLevel Eye-Hye – Remote Indicator

2 – Guided Wave Radar – Remote Indicator

1 – Gage Glass – Direct Reading Indicator

The center water column stabilizes the level and may also contain vertically oriented conductivity probes for alarm or trip functions.

Select the orientation of each instrument among the 4 locations on this assembly plan view to best suit your boiler installation and the structure around it, while considering operator or inspector access to the drum.

Benefits of the LevelMax Optima System

-

Provides local and remote drum level monitoring

-

Maximum reliability with multiple technologies eliminates common mode failures

-

Customize instrument locations and select the best position on bridle

-

Consider assemblies for either end of the drum

-

Eliminate expensive field fabrication with a ready-to-install bridle assembly

-

Systems are available for ordinary and classified area locations

-

This LevelMax system provides you with assurance for your boiler level and the safety of your personnel and plant equipment

Resources:

-

Bulletin: